A Comprehensive Supply Chain for Core Intermediates in Diabetes Treatment

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

API synthesis (active pharmaceutical ingredient synthesis) is the core link of the pharmaceutical industry. It refers to the complete process of converting basic chemical raw materials into active pharmaceutical molecules (API) with therapeutic effects through chemical reactions.

API synthesis is not only a combination of chemical reactions, but also involves multiple steps, such as selecting synthesis routes, optimizing reaction conditions, handling impurities, and large-scale production. This process is not only a simple molecular construction, but also a precision engineering that needs to balance efficiency, cost, safety and compliance.

The production of many drugs cannot be separated from this step. As a chemist with more than ten years of experience in the pharmaceutical field, specializing in the synthesis of API (active pharmaceutical ingredients) and intermediates, today, I want to share some of the valuable lessons I’ve learned over the years, especially focusing on the fascinating yet complex world of API synthesis.

From molecular design to industrialization

From laboratory tests (milligram level) to commercial production (ton level), it is necessary to go through stages such as route screening, process optimization, impurity control, and equipment adaptation. For example, an anticancer drug intermediate may be synthesized through 7 steps of reaction, and the yield of each step must be greater than 90% to ensure that the final cost is controllable.

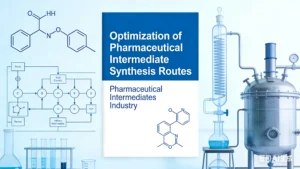

Route selection

API synthesis is more than just a series of chemical reactions; it’s a delicate balance of art and science. There are often multiple ways to synthesize a particular API, but not all routes are equally efficient or cost-effective. Chemists have to choose among hundreds of potential routes:

Classic route | Uses mature reactions (such as Suzuki coupling), but may produce heavy metal residues |

Biocatalytic route | Enzymatic synthesis is more environmentally friendly, but enzyme stability is a big challenge |

Continuous Flow Process | Improve safety, but high equipment investment |

For example, in the synthesis of a hypoglycemic drug, photocatalysis was used to replace traditional oxidants, reducing the number of steps from 5 to 3 and reducing wastewater by 80%.

If a single impurity exceeds 0.1%, the source must be identified. A previous case: During the synthesis of a chiral drug, it was found that enantiomeric impurities increased rapidly with scale-up, and the impurities were eventually controlled below 0.05% by adding chiral ligands.

No matter how well-prepared we are, issues can arise during the synthesis process. One of the most frequent problems is low yield.

This can be due to various reasons, such as incomplete reactions or side reactions. In my experience, the key to addressing this is meticulous monitoring of the reaction progress.

Techniques like HPLC (High-Performance Liquid Chromatography) can be incredibly useful in identifying where things might be going wrong.

Another common problem is the formation of impurities. As we all know, impurities can affect the efficacy and safety of the final product, so they must be minimized.

An effective strategy I have found is to optimize reaction conditions, such as temperature and pH, to favor the formation of the target product. In addition, using high-purity starting materials and reagents can significantly reduce impurities.

Innovation is the lifeblood of our industry. With the increasing demand for new and improved pharmaceuticals, the ability to innovate in API synthesis is more important than ever.

One area where I’ve seen significant progress is green chemistry. By using more environmentally friendly solvents and reagents, we can reduce the environmental impact of our processes while still achieving high-quality APIs.

Another exciting development is the use of advanced analytical techniques to guide synthesis. Tools like real-time monitoring and predictive modeling can help us anticipate potential issues and adjust our processes accordingly. This not only improves but efficiency also enhances the overall quality of the final product.

At our pharmaceutical company, we have a range of high-quality APIs and intermediates, covering anti-tumor intermediates and APIs, anti-diabetic intermediates and APIs, cardiovascular intermediates and APIs. We have a large team of experienced chemists and technicians who are always at the forefront of the industry to ensure that our products meet the highest standards of purity and efficacy.

Whether you are looking for a specific API or need a custom synthesis, we have extensive expertise and resources to meet your needs.

The difference between a good API and a great API lies in the unknown details – impurities you never detect, scale-up challenges you solve in advance, and sustainable advantages in reducing costs.

After decades perfecting this balance, our team now offers:

Custom Synthesis: From 5-gram feasibility studies to 500 kg commercial runs

Process Intensification: Double your yield or halve your steps—guaranteed

Free Sample: Free samples are provided for quality testing

If you have any questions about API synthesis or would like to discuss a specific project, feel free to reach out. sunqian0123@gmail.com

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

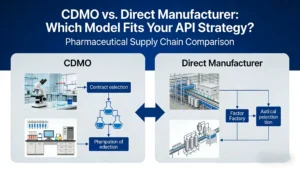

Drawing from on-the-ground experience in China’s top pharma clusters, this guide cuts through the jargon to reveal when to partner for complex innovation and when to buy from the workhorses of mature production.

This case study, based on publicly available academic literature and patents, focuses on the application of synthetic route optimization in improving the yield and purity of Active Pharmaceutical Ingredients (APIs).

Leading provider of high-quality APIs and intermediates. Contact us for innovative solutions and expert support.