As a chemical synthesist with over a decade in the field, I’ve handled at least a hundred different intermediates. Today, I want to discuss a particularly critical aspect of our CDMO industry—advanced pharmaceutical intermediates.

To put it plainly, they are the “pre-made ingredients” for constructing complex drug molecules, though the reality is far more intricate than this analogy suggests.

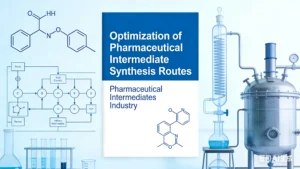

When I first started, I viewed intermediates as mere transitional products in the synthesis pathway. That changed completely when I worked on an anti-cancer drug project. We hit a roadblock at the third step, with yields stubbornly refusing to improve. Then we introduced a cleverly designed chiral intermediate.

It was like unlocking hidden potential—not only did we condense three steps into two, but we achieved a final purity exceeding 99.5%. That moment made me realize: choosing the right intermediate can transform an entire synthetic route into a work of art.

What are Advanced Pharmaceutical Intermediates?

First, let’s clarify this concept: What defines an advanced pharmaceutical intermediate? These are high-purity, structurally defined compounds serving as building blocks for multi-step synthesis of active pharmaceutical ingredients (APIs).

Unlike basic intermediates, they typically feature chiral centers, sensitive functional groups, and specific stereochemical structures, demanding expert-level process control and analytical precision.

Why Prioritize Advanced Intermediates?

First and foremost, it’s about time. New drug development is like running a marathon where everyone is sprinting. An optimized intermediate helps us avoid numerous pitfalls. For instance, air-sensitive functional groups protected at the intermediate stage save immense trouble during scale-up—a lesson learned the hard way.

Second, quality stability. I vividly recall a project last year where switching intermediate suppliers resulted in two out of three batches having different impurity profiles, nearly causing a clinical sample shortage.

Later, we locked in a GMP-certified intermediate supplier whose batch consistency was exceptional—like standardized parts that fit perfectly. This consistency is crucial for passing audits.

Modern drug molecules are becoming increasingly complex, especially those with multiple chiral centers. This is where the value of dedicated intermediates shines.

I recall working on a neuropharmaceutical where the key intermediate resembled a precision-engineered Lego brick—complete with pre-designed functional groups that integrated seamlessly into subsequent steps. It’s like having pre-finished building materials: you don’t have to start from firing bricks when constructing a house.

Costs must be evaluated holistically. While quality intermediates may have a higher unit price, they often prove more economical overall. Why? Because their synthesis routes are engineered from the outset to optimize purification, yield, and waste management.

In one diabetes drug project, using custom intermediates eliminated two reaction steps and reduced solvent consumption per kilogram of API by 60%—that’s real money saved.

How do We Approach this in Practice?

When selecting intermediates, our team has developed a habit: the earlier we get involved, the better. We collaborate with specialized partners right from the route design phase. Chemists who truly understand the field can propose designs that are genuinely eye-opening.

Once, we needed to synthesize a polycyclic molecule. Our lab route worked in small scale but failed at scale-up. The team then proposed a novel intermediate that cleverly bypassed the site prone to isomerization. Solutions rooted in deep chemical understanding are truly invaluable.

We’ve also learned hard lessons in quality control. Now, for critical intermediates, our standard is simple: apply the same rigor as for APIs. While seemingly demanding, this ensures subsequent steps won’t amplify existing issues.

Moreover, the technical documentation provided by professional suppliers is exceptionally detailed, which is a godsend when compiling registration dossiers.

Looking Ahead

I see exciting shifts unfolding in this field. The adoption of continuous flow technology enables “just-in-time” synthesis of certain intermediates, significantly enhancing safety. Green chemistry requirements are also driving us to develop more environmentally friendly synthetic routes.

Recently, we’ve been experimenting with AI tools to assist in route design. We’ve found that some of the intermediate structures recommended by these tools are remarkably ingenious—approaches that traditional thinking might easily overlook.

However, these tools ultimately cannot replace a chemist’s intuition and experience—that “feel” for molecular behavior, which is accumulated through thousands of experiments.

Finally, a Personal Note

After so many years in synthesis, I increasingly feel that choosing the right intermediate is an art. A well-chosen intermediate can make complex syntheses flow like water. It’s not just a structural transformation; it’s the pacing device for the entire project.

If you’re also in CDMO, my advice is: Treat every intermediate with care, just as you would every partner on your synthetic route. They may not appear in the final molecule, but these “unsung heroes” determine whether our drugs reach patients efficiently, economically, and compliantly.

The journey ahead is long, but witnessing molecules transform from blueprints into medicines through our hands—that sense of accomplishment is the greatest motivation for us chemical synthesists.

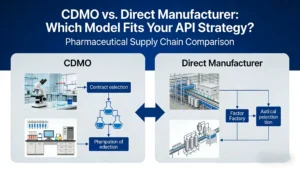

How Tianming Pharmaceuticals Supports CDMO Projects

Tianming Pharmaceuticals Group specializes in designing, synthesizing, and supplying advanced pharmaceutical intermediates for global CDMOs and API manufacturers. With over a decade of industry experience, our R&D and production teams combine chemical expertise with deep understanding of regulatory requirements.

Our Core Strengths:

- Comprehensive Product Portfolio:

Covering therapeutic areas including antidiabetic, cardiovascular, and anticancer drugs.

- Custom Synthesis & Process Optimization:

Tailoring synthesis routes to meet specific client requirements.

- GMP & ISO Certified Manufacturing:

Ensuring rigorous quality control, stability, and traceability at every step.

- Rapid Delivery & Global Export Expertise:

Established logistics and compliance systems guaranteeing worldwide distribution.

Our mission is simple—to help partners shorten R&D cycles, enhance product quality, and achieve sustainable cost-effectiveness.

Contact Tianming Pharmaceutical Group

Email: sunqian0123@gmail.com

WhatsApp: +86 176 6371 3557