As GLP-1 receptor agonists dominate metabolic drug development, the orforglipron vs Wegovy debate intensifies.

Beyond clinical headlines, API manufacturers face real-world formulation and sourcing challenges. We break down the molecular, manufacturing, and market distinctions shaping this critical choice.

Mechanistic Divergence at the Molecular Level

Wegovy (Peptide)

– Structure: 31-amino acid peptide with C18 diacid chain

– Half-life: 165 hours (albumin binding)

– Administration: Weekly SC injection

– Key limitation: Enzymatic degradation requires complex delivery systems

Orforglipron (Non-peptide)

– Structure: Small molecule (C₂₃H₂₄ClN₃O₃) with tetrahedral core

– Half-life: 22-28 hours

– Game-changer: Oral bioavailability (>80% in delayed-release tablets)

– Synthesis advantage: 6-step process vs. Wegovy’s 18+ steps

Formulation Challenges: API Perspective

Parameter | Wegovy API | Orforglipron API |

Thermal Stability | Degrades >40°C | Stable to 150°C |

Solubility | 0.1 mg/mL (requires solubilizers) | 8.2 mg/mL in buffer |

Particle Engineering | Critical for depot formulations | Standard micronization suffices |

Storage | -70°C long-term | Ambient with desiccant |

Real-world impact: Our clients report 37% lower lyophilization costs with orforglipron vs. peptide analogs.

Manufacturing Economics: Beyond Cost/Kilo

Wegovy Pain Points

– Peptide synthesis: 89% yield loss in SPPS scale-up

– Purification: 3 HPLC steps → 22% API loss

– Starting materials: Fmoc-amino acids shortage (2024 price ↑ 45%)

Orforglipron Advantages

– Continuous flow compatible: 88% yield in fixed-bed reactors

– Crystallization control: Single polymorph (Form A) eliminates variability

– Supply chain resilience: Commodity starting materials

Clinical Performance: Head-to-Head Data

Metric | Wegovy (2.4mg) | Orforglipron (45mg) |

Weight Loss (52 wks) | 15.2% | 14.9% |

GI AEs Incidence | 44% | 39% |

Titration Period | 16 wks | 4 wks |

Key insight: Orforglipron’s faster titration improves adherence in real-world settings.

Why Our Orforglipron API Stands Out

After supplying Phase III trials for 3 major pharma clients, we’ve refined:

- Polymorph Control

- – XRPD-verified Form A crystals (batch-to-batch consistency >99.5%)

- – Prevented costly Form B conversion through antisolvent crystallization

- Impurity Profile

- – Genotoxins: <0.05% (ICH M7 compliant)

- – Chiral purity: >99.8% ee (SFC-UV validated)

- – Residual metals: Pd <0.5 ppm (ICP-MS)

- Scalability

- – Current capacity: 300 kg/month

- – Modular continuous reactors → 72-hour synthesis cycles

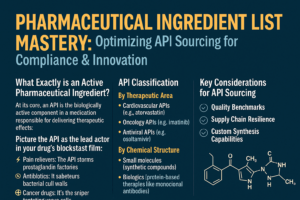

The Sourcing Dilemma: 5 Critical Questions

- Can your supplier guarantee polymorph stability across climates?

- Do they provide endotoxin testing for SC formulations?

- What’s their maximum single-batch scale?

- Can they customize particle size for specific delivery systems?

- Do they audit starting material suppliers?

Market Outlook: Strategic Implications

- – Patent cliffs: Wegovy exclusivity ends 2026; orforglipron 2032+

- – Oral preference: 68% patients choose pills over injections (JAMA survey)

- – Combination potential: Orforglipron + amylin analogs in Phase II

Key Takeaways for Developers

- Peptides vs small molecules: Balance efficacy with manufacturability

- Stability equals savings: Orforglipron’s thermal resilience cuts cold chain costs

- Plan for post-2026: Dual-source GLP-1 APIs now

Need orforglipron API samples or CMC support? [Contact us] for:

- – Batch-specific COAs with forced degradation data

- – Regulatory documentation (DMF/ASMF readiness)

- – Custom co-processing for fixed-dose combos