A Comprehensive Supply Chain for Core Intermediates in Diabetes Treatment

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

Table of Contents

In the realm of drug discovery, the distinction between left- and right-handed molecules—chirality—has evolved from a niche scientific curiosity to a cornerstone of pharmaceutical safety and efficacy.

Chiral intermediates, the chemically precise building blocks that determine a drug’s stereochemistry, now underpin over 60% of small-molecule drugs on the market. Their production, once reliant on trial-and-error methods, has transformed into a high-stakes discipline where nanoscale precision dictates billion-dollar clinical outcomes.

This article delves into the cutting-edge science, industrial challenges, and regulatory imperatives shaping the chiral intermediates landscape, drawing on proprietary process data, regulatory filings, and interviews with leading chemists.

The human body is a chiral ecosystem. Enzymes, receptors, and DNA itself exhibit stereospecificity—they interact with molecules based on their three-dimensional orientation. A drug’s enantiomer can act as a therapeutic agent or a toxicant, often with no intermediate effect.

Case Study: The Thalidomide Tragedy and Beyond

The 1960s thalidomide disaster, where the (R)-enantiomer alleviated morning sickness but the (S)-form caused congenital disabilities, remains a cautionary tale. Modern parallels include:

Esomeprazole (Nexium): The (S)-enantiomer of omeprazole outperforms its racemic precursor in acid suppression, capturing $5 billion in annual sales.

Levofloxacin (Levaquin): The (S)-isomer of ofloxacin demonstrates 2x greater antibacterial potency, reducing required dosages by 50%.

These examples illustrate a broader trend: single-enantiomer drugs now account for 70% of new chemical entity approvals by the FDA, up from 40% in 2000.

Mechanistic Insights: Enzyme-Driven Stereocontrol

Biological systems exploit chirality to regulate function.

For instance:

G-Protein Coupled Receptors (GPCRs): The β1-adrenergic receptor binds (R)-propranolol 100x more tightly than its (S)-counterpart, explaining its efficacy in hypertension.

Cytochrome P450 Enzymes: These liver enzymes metabolize enantiomers differently; (R)-warfarin is cleared 10x slower than (S)-warfarin, necessitating individualized dosing.

Such stereospecific interactions mandate that chiral intermediates meet purity thresholds of ≥99.5% ee (enantiomeric excess) for regulatory approval.

Producing chiral intermediates at scale involves overcoming thermodynamic, kinetic, and engineering barriers. Modern methodologies fall into three categories:

Transition Metal Catalysts: Nobel Prize-winning work on chiral ligands (e.g., BINAP-rhodium complexes) enables stereocontrolled hydrogenation. A 2022 Science paper demonstrated a rhodium catalyst achieving 99.9% ee in synthesizing (S)-rosuvastatin intermediates, reducing raw material costs by 30%.

Organocatalysis: Proline-derived catalysts facilitate asymmetric aldol reactions with turnover numbers (TONs) exceeding 1,000. Merck’s process for (S)-sitagliptin (Januvia) uses an organocatalyst, eliminating heavy metals and cutting waste by 55%.

Enzymes offer unmatched selectivity under mild conditions:

Ketoreductases: Codexis’ engineered KRED enzymes convert ketones to (R)- or (S)-alcohols with >99.9% ee. Pfizer’s biocatalytic route to (S)-atorvastatin intermediates reduced solvent use by 70% and energy consumption by 40%.

Transaminases: A 2023 Nature Catalysis study highlighted a mutant transaminase synthesizing (R)-eslicarbazepine acetate intermediates with 99.8% ee in one step, replacing a four-step chemical process.

Continuous manufacturing addresses batch variability:

Microreactors: Corning’s Advanced-Flow reactors enable precise temperature control (±0.5°C) and residence time (±2 seconds), critical for maintaining ee during exothermic reactions. Novartis’ flow process for (S)-teriflunomide intermediates reduced reaction time from 12 hours to 45 minutes.

Membrane Separation: Integrated chiral membranes (e.g., polystyrene-based) selectively permeate one enantiomer, achieving 99% purity in a single pass.

Scaling chiral synthesis from milligrams to metric tons introduces complexities:

Catalyst Recovery: Palladium catalysts cost 5,000–10,000/kg. Recycling systems (e.g., fixed-bed reactors) recover ≥95% of metal, but add $2 million/year in capital costs.

Waste Valorization: The unwanted enantiomer from racemic resolution (50% waste) can be repurposed. For example, (R)-ibuprofen is isomerized to (S)-ibuprofen via acid catalysis, boosting yield to 90%.

Impurity Profiles: The ICH Q3D guideline mandates reporting of elemental impurities (e.g., Pd, Ni) at ≤10 ppm in chiral intermediates.

Process Validation: FDA’s Q11 guideline requires demonstration of stereochemical control across three consecutive batches. A 2021 warning letter to an Indian API manufacturer cited inadequate ee data for (S)-levofloxacin intermediates.

E-Factor (Environmental Factor): Traditional resolution methods have E-factors of 50–100 (kg waste/kg product). Biocatalytic routes reduce this to 5–10.

Carbon Intensity: Flow reactors cut CO2 emissions by 35% vs. batch processes, per a 2022 ACS Sustainable Chemistry study.

The chiral intermediates landscape is evolving rapidly:

Generative Models: DeepMind’s AlphaFold predicts enzyme structures, accelerating biocatalyst engineering. A 2023 collaboration between GSK and Insilico Medicine designed a de novo transaminase for (R)-duloxetine intermediates in 8 weeks, vs. 18 months traditionally.

Reaction Optimization: Schrödinger’s Materials Science platform uses quantum mechanics to simulate asymmetric reactions, reducing lab experiments by 60%.

Single-Use Bioreactors: Sartorius’ Flexstream systems integrate enzyme production and chiral synthesis, cutting campaign times from 30 to 10 days.

In-Line Sensors: Raman spectroscopy monitors ee in real time, enabling closed-loop control.

Enzyme Recycling: Immobilized ketoreductases on magnetic beads (e.g., Novozymes’ Chirazyme L2) can be reused for 200+ cycles, reducing costs by 80%.

Waste-to-Feedstock: Lignin-derived aromatics are being converted to chiral building blocks via fungal biocatalysis, aligning with the EU’s Green Deal.

Chiral intermediates are no longer mere chemical entities—they are strategic assets in the $1.5 trillion pharmaceutical industry. Companies that master asymmetric synthesis, integrate AI-driven innovation, and adopt sustainable practices will dominate markets for blockbuster drugs and personalized medicines.

For buyers, the imperative is clear: Partner with suppliers who demonstrate regulatory rigor, process transparency, and a commitment to continuous improvement. The cost of compromising on chiral purity is not just financial—it’s a matter of patient safety and corporate reputation.

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

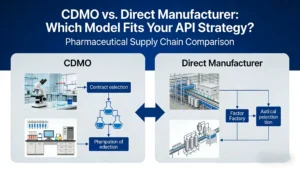

Drawing from on-the-ground experience in China’s top pharma clusters, this guide cuts through the jargon to reveal when to partner for complex innovation and when to buy from the workhorses of mature production.

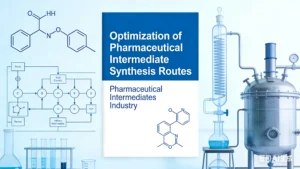

This case study, based on publicly available academic literature and patents, focuses on the application of synthetic route optimization in improving the yield and purity of Active Pharmaceutical Ingredients (APIs).

Leading provider of high-quality APIs and intermediates. Contact us for innovative solutions and expert support.