A Comprehensive Supply Chain for Core Intermediates in Diabetes Treatment

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

Table of Contents

In modern pharmaceutical manufacturing, pharmaceutical intermediates serve as the critical bridge connecting basic chemical raw materials to final active pharmaceutical ingredients (APIs).

With the rapid advancement of global drug innovation, generic drug expansion, and CDMO outsourcing, high-quality, traceable, and stably supplied pharmaceutical intermediates have become one of the most crucial decision factors for pharmaceutical companies when selecting suppliers.

To help industry readers better understand the complete production pathway from design to mass production, this article systematically analyzes pharmaceutical intermediate manufacturing processes and critical quality control points, providing practical reference for corporate technical teams, procurement personnel, and compliance officers.

Although drug structures vary in complexity, most pharmaceutical intermediates follow this systematic production framework:

1、Process Route Design (Route Selection)

The objective is to select the most economical, stable, and safe synthetic route, considering:

An excellent supplier should possess:

2、Lab-Scale Synthesis

This phase validates route feasibility, focusing on:

Analytical methods (HPLC, GC, NMR, KF, LC-MS, etc.) are also established in this stage.

3、Pilot Scale-up

Pilot scale-up represents the critical “experiential” phase within the EEAT framework, with primary objectives including:

Compliant CDMOs or intermediate plants typically require:

4、Commercial Manufacturing

This phase requires facilities to possess:

Critical steps include:

5、Quality Control and Release (QA/QC Release)

Testing typically includes:

Release criteria must comply with:

Impurities pose fundamental risks to final API quality. Ensure:

Qualified suppliers must provide:

Reaction temperature, time, stirring speed, pH, and solvent ratios all impact final quality. Must:

Includes:

Aims to remove structurally similar impurities and ensure batch consistency.

Suppliers must ensure:

Below are the EEAT dimensions most prioritized by pharmaceutical companies when selecting partners:

✔ E (Expertise)

👉 This is the foremost criterion for all intermediate selection.

✔ E (Experience)

👉Experienced manufacturers significantly reduce technical risks—an industry default standard.

✔ A (Authoritativeness)

👉These serve as objective proof of supplier authority and credibility.

✔ T (Trustworthiness)

👉Trust is the cornerstone of long-term partnerships.

Enhances safety, yield, and environmental performance.

Reduces solvent consumption and wastewater discharge.

Enables faster, more accurate data analysis and prediction.

Unified supply from intermediates to APIs improves stability and cost advantages.

As a specialized manufacturer of pharmaceutical intermediates and APIs, we possess extensive expertise in oncology, cardiovascular, diabetes, anti-infective, and other therapeutic areas.

We offer:

If you are seeking a reliable pharmaceutical intermediate supplier, contact us for technical documentation and quotations. We provide robust support for your API development and production needs.

Email: sunqian0123@gmail.com

WhatsApp: +86 17663713557

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

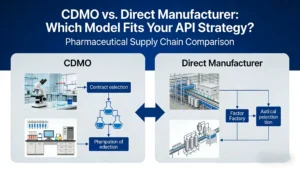

Drawing from on-the-ground experience in China’s top pharma clusters, this guide cuts through the jargon to reveal when to partner for complex innovation and when to buy from the workhorses of mature production.

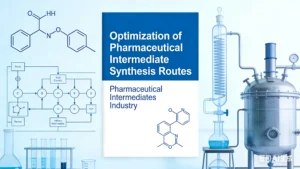

This case study, based on publicly available academic literature and patents, focuses on the application of synthetic route optimization in improving the yield and purity of Active Pharmaceutical Ingredients (APIs).

Leading provider of high-quality APIs and intermediates. Contact us for innovative solutions and expert support.