A Comprehensive Supply Chain for Core Intermediates in Diabetes Treatment

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

The fast pace and high stress of modern society can easily lead to overeating, which in turn leads to large fluctuations in blood sugar, and many people will suffer from diabetes without realizing it. Today, we are going to talk about the new star in the field of diabetes treatment – Linagliptin! Learn about its mechanism of action and see how it controls your blood sugar steadily.

Briefly, Linagliptin is a novel, highly potent and selective inhibitor of dipeptidyl peptide-4 (DPP-4), which is mainly used for the treatment of type 2 diabetes mellitus.

Below is the chemical information for Linagliptin:

Product Name | Linagliptin |

CAS | 668270-12-0 |

Molecular formula | C25H28N8O2 |

Molecular weight | 472.54 |

The main mechanism of action of DPP-4 inhibitors is to reduce the inactivation of glucagon-like peptide-1 (GLP-1) in the body by inhibiting the activity of the enzyme DPP-4. GLP-1 is a postprandial hormone with pro-insulinotropic properties that promotes the release of insulin from pancreatic β-cells while inhibiting the secretion of glucagon by pancreatic α-cells, thereby lowering blood glucose.

Since GLP-1 acts in a glucose concentration-dependent manner, it is able to promote insulin secretion when blood glucose is elevated, but does not act when blood glucose is normal or low, thus avoiding hypoglycemia.

1. Unique pharmacological mechanism

Linagliptin is a dipeptidyl peptidase-4 (DPP-4) inhibitor, which enhances insulin secretion and inhibits glucagon release by inhibiting DPP-4 enzyme activity and prolonging the action of endogenous glucagon-like peptide-1 (GLP-1) and glucose-dependent insulinotropic polypeptide (GIP). This mechanism allows Linagliptin to lower blood glucose with a low risk of hypoglycemia because its action is dependent on blood glucose levels.

2. Good hypoglycemic effect

Clinical studies have shown that Linagliptin, when used as monotherapy or in combination with other oral hypoglycemic agents, can significantly reduce glycated hemoglobin (HbA1c) levels and improve glycemic control. This glucose-lowering effect is stable and long-lasting, helping to reduce diabetes-related complications.

3. High safety

Linagliptin has a favorable safety profile and is well tolerated. The incidence of adverse reactions was similar or lower in Linagliptin-treated patients compared to placebo. In addition, Linagliptin does not require dosage adjustments based on a patient’s renal function, which makes it uniquely advantageous in diabetic patients with comorbid renal insufficiency.

However, it should also be noted that there are case studies suggesting that Linagliptin may cause pancreatitis, and clinicians should be vigilant about this, although the exact mechanism is unknown.

4. Convenient dosing

Linagliptin is easy to administer, as it can be taken orally once daily without frequent dose adjustments or monitoring of blood glucose levels. This improves patient compliance and quality of life, and helps to maintain stable blood glucose in the long term.

5. Wide applicability

In addition to being suitable for patients with type 2 diabetes, Linagliptin may have additional benefits for patients at high risk of stroke. Studies have shown that Linagliptin is able to stimulate neuroprotection while largely reducing post-stroke brain damage. This finding opens up new possibilities for the use of Linagliptin in patients with diabetes combined with cerebrovascular disease.

Linagliptin is a potent and selective dipeptidyl peptidase-4 (DPP-4) inhibitor mainly used for the treatment of type 2 diabetes. In its manufacturing process, the synthetic challenges mainly arise from the complexity of the chemical reaction, the selection and cost of raw materials, the purity and yield of the product, and the feasibility of industrial production.

During the manufacturing process of linagliptin (Linagliptin), it is crucial to ensure product purity. To achieve this, advanced analytical methods such as high performance liquid chromatography (HPLC) and nuclear magnetic resonance (NMR) can be used. The following are specific descriptions of these methods in ensuring the purity of Riglitazone:

1. High Performance Liquid Chromatography (HPLC)

Principle: HPLC is a technique for separating different substances based on the difference in partition coefficients between the stationary and mobile phases. It utilizes a high-pressure pump to pump the mobile phase (usually a solvent mixture) onto a column where the sample is separated based on the strength of interaction with the stationary phase.

Applications: In the synthesis of Riglitazone, HPLC is used to monitor the progress of the reaction, detect impurities, and determine the purity of the product. By comparing the chromatogram of the sample with that of the standard, it is possible to determine whether the purity of the product meets the requirements.

Advantages: HPLC has the advantages of high separation efficiency, high sensitivity and good reproducibility, and is one of the commonly used methods for the determination of drug purity.

2. Nuclear magnetic resonance (NMR)

Principle: NMR is a technique based on the generation of signals by energy level jumps of atomic nuclei in an external magnetic field. It utilizes radiofrequency pulses to excite the nuclei in the sample, causing them to undergo energy level jumps, and then detects the signals released when they jump back to the ground state, thus obtaining structural information about the sample.

Applications: In the synthesis of linagliptin, NMR can be used to confirm the structure of the product, including the chemical environments of the hydrogen and carbon atoms as well as the connections between them. In addition, NMR can be used to detect trace amounts of impurities and isomers.

Advantages: NMR can provide rich structural information and is irreplaceable for determining the purity and structure of compounds. However, its operation is relatively complex and costly.

Specialized API manufacturers are typically well-versed in following Good Manufacturing Practices (GMP) guidelines set by regulatory bodies such as the FDA (Food and Drug Administration) in the US, EMA (European Medicines Agency), and others. Compliance with GMP ensures that the manufacturing process meets stringent quality standards, which are crucial for the safety and efficacy of the final pharmaceutical product.

In short, teaming up with a specialized API manufacturer is a smart move for your pharmaceutical business. It ensures GMP compliance and scalability for global demand, so you can be sure your products meet the highest standards of quality, safety, and efficacy.

At Tianming Pharmaceutical Group, we’ve been producing bulk Intermediates and APIs for over 10 years, including high-quality linagliptin. Our commitment to excellence, combined with our industry expertise and advanced manufacturing capabilities, has earned us a reputation for reliability and trustworthiness in the global pharmaceutical market.

We invite you to join our esteemed list of customers and experience the benefits of partnering with a specialized API manufacturer. If you’re looking for linagliptin or any other API, Tianming Pharmaceutical is here for you. Give us a shout today to chat about your needs and how we can help your pharmaceutical business thrive.

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

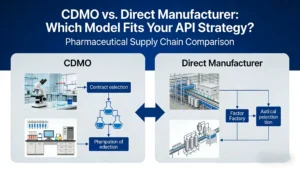

Drawing from on-the-ground experience in China’s top pharma clusters, this guide cuts through the jargon to reveal when to partner for complex innovation and when to buy from the workhorses of mature production.

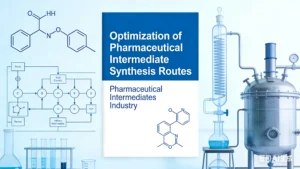

This case study, based on publicly available academic literature and patents, focuses on the application of synthetic route optimization in improving the yield and purity of Active Pharmaceutical Ingredients (APIs).

Leading provider of high-quality APIs and intermediates. Contact us for innovative solutions and expert support.