A Comprehensive Supply Chain for Core Intermediates in Diabetes Treatment

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

There are various types of pharmaceutical intermediates and the development technologies of such intermediates in the recent years. Pharmaceutical intermediates are important chemical products and materials used in the production of pharmaceutical drugs and are one of the most important fine chemicals. The advancement in the pharmaceutical intermediates has been on the rise in the past few years.

Advanced level techniques like combinatorial chemistry, biocatalysis, cellular biochemistry, chiral chemistry, peptide synthesis and carbohydrate synthesis have enhanced the efficiency of production and have reduced the environmental impact.

Vitamin Intermediates

Intermediates for producing vitamins, such as sorbitol for Vitamin C, phytol for Vitamin E, and β-ionone, a key intermediate for synthesizing Vitamins E and A, are in high demand with promising market prospects.

Heterocyclic Compounds

Widely used in pharmaceuticals, agrochemicals, and veterinary medicine as active ingredients and intermediates, heterocyclic compounds serve as core structures. Drugs like Losartan Potassium for hypertension are examples of heterocyclic compounds. Major heterocycles include imidazole, thiazole, triazole, pyridine, pyrimidine, piperazine, triazine, and their derivatives.

Fluorinated Compounds

Incorporating fluorine into pharmaceutical intermediates enhances efficacy. Fluorinated drugs, widely used globally, offer benefits such as low dosage, high efficacy, low toxicity, and strong metabolic stability, making them critical in the pharmaceutical industry.

Chiral Compounds

Derived through asymmetric synthesis or resolution based on stereochemistry, chiral compounds have extensive applications. Advancements in biotechnology have enabled the use of microorganisms to develop specific enzymes and strains for resolving chiral products.

These compounds are essential for producing chiral amines, amino acids, and other intermediates. To expedite new drug development, reduce costs, and enhance capital efficiency, intermediates are often outsourced for custom manufacturing. Companies like Medicilon offer chemical technology services, optimizing API and intermediate processes to develop safe, cost-effective, and scalable production methods.

Biochemical Compounds

Utilizing DNA recombination, cell engineering, and enzyme engineering technologies, biochemical compounds are used to develop treatments for cardiovascular diseases, diabetes, hepatitis, cancer, and anti-aging therapies, while modern biotechnology transforms traditional pharmaceutical manufacturing.

The development and production of pharmaceutical intermediates are highly technical processes, far from being simple manufacturing tasks. Companies must offer specialized technologies, including:

Targeted Nitration Technology

Through selective nitration, the isomer ratio of benzene and aromatic fused rings can be adjusted using clean nitration methods, reducing costs and pollution while achieving green nitration.

High-Temperature and High-Pressure Reaction Technology

Used to minimize reaction volume, reduce reagent costs, and decrease waste, this technology is essential for chemical processes like condensation, polymerization, alkylation, sulfonation, and hydrogenation under industrial conditions.

Condensation Technology

Techniques like Mannich and Aldol condensations produce large molecules, with catalyst selection being a critical factor for success.

Controlled Oxidation Technology

Oxidizing aromatic compounds to aldehydes is crucial, as these intermediates are used in pharmaceuticals and agrochemicals. Controlling oxidation to stop at aldehydes rather than further oxidation poses significant challenges, including selecting appropriate oxidants.

Fluorination Technology

Introducing fluorine into organic intermediates is vital for synthesizing fluorinated compounds. Successfully integrating fluorine into parent molecules is a key area of focus.

Hydrogenation Reduction Technology

Compared to traditional reduction methods like iron or sodium sulfide reduction, hydrogenation offers higher yield, lower cost, and reduced pollution. The success of hydrogenation depends on catalyst selection and application.

Asymmetric Synthesis

Asymmetric synthesis has become a critical area in organic synthesis for producing chiral drugs and intermediates. Patents cover asymmetric reactions such as reductions, condensations, alkylations, oxidations, and cyanohydrin reactions.

Biocatalysis for Asymmetric Reactions

Enzymes, recognized as optimal chiral catalysts, are used extensively in asymmetric catalysis. Research and development focus on enzymatic reductions, oxidations, hydrolysis, and esterification, with oxidoreductases and hydrolases being the most studied enzyme classes.

Pharmaceutical intermediate manufacturers must also provide GMP-compliant custom synthesis services for global pharmaceutical giants. Their production systems undergo rigorous government inspections, while project management, process optimization, environmental health and safety (EHS), and information security capabilities are audited by clients.

Tianming Pharmaceuticals specializes in the development and production of high-quality pharmaceutical intermediates and APIs, focusing on delivering customized solutions and innovative technologies to meet global industry demands.

Contact us now to experience our services

WhatsApp:+86 133 6541 4469

Email: damon.wang@sdsihuanpharm.com

End-to-end supply chain for anti-diabetic intermediates. Covering DPP-4, SGLT-2 inhibitors & GPR40 agonists. Stable, compliant, scalable.

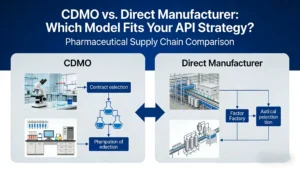

Drawing from on-the-ground experience in China’s top pharma clusters, this guide cuts through the jargon to reveal when to partner for complex innovation and when to buy from the workhorses of mature production.

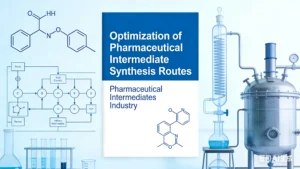

This case study, based on publicly available academic literature and patents, focuses on the application of synthetic route optimization in improving the yield and purity of Active Pharmaceutical Ingredients (APIs).

Leading provider of high-quality APIs and intermediates. Contact us for innovative solutions and expert support.